Introduction

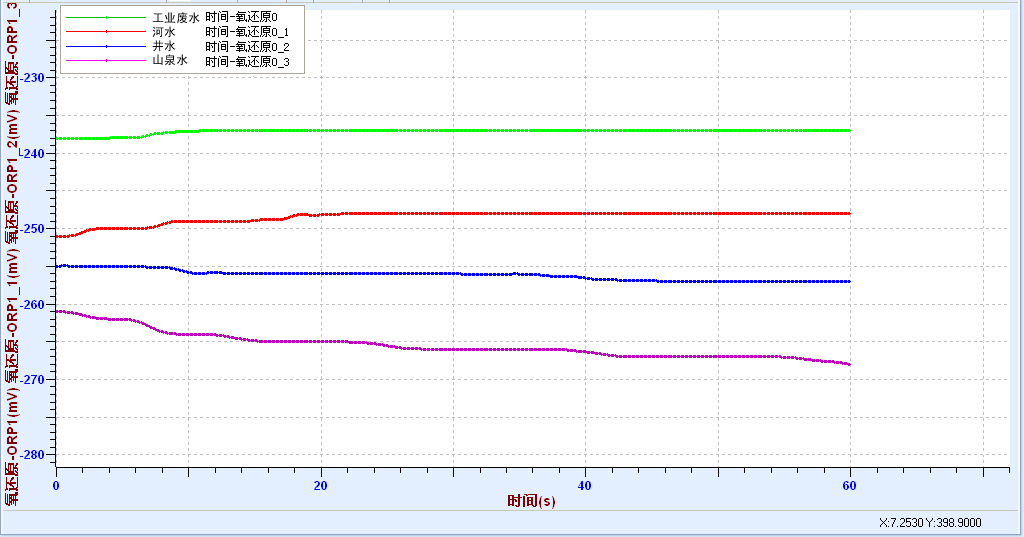

♦ ORP Sensor is used to measure the reduction solution redox potential (ORP). ORP value is the index of redox ability of solution. It is also can be used to measure redox potential and suitable for solution sample including sewage treatment and biological fermentation in the lab.

Usage

♦ Take out ORP electrode from the pack. Connect electrode to ORP Sensor.

♦ Connect sensor to datalogger and datalogger to computer.

♦ Screw off electrode from the cover which contains solution.

Immerse it into the liquid to be measured. Measure ORP potential using experiment software.

♦ Clean the electrode after using. Place it back to the cover containing solution.

Notes

♦ The Oxidation-Reduction Potential Sensor needs no calibration when using. It can be used directly. If there is doubt for the quality of ORP electrode or the test result, it is suggested to use the ORP standard solution to check whether the potential is between 200 and 275mv. Based on which, it can judge whether the ORP electrode or instrument is good or not.

♦ The surface of the ORP measuring electrode (platinum or gold) should be shining, where the coarse or polluted surface will affect the potential (mv) of electrode. The following method can be used to clean and activate:

(1)Inorganic pollution: Dip the electrode into the 0.1mol/L dilute hydrochloric acid for 30 minutes. Use purified water to clean. Dip it into the 3.5mol/L potassium chloride solution for 6 hours.

(2)Organic oil pollution and oil film pollution: use cleaning solvent to clean the platinum or gold. Use purified water to rinse. Dip it into the 3.5mol/L potassium chloride solution for 6 hours.

(3)The platinum-gold surface is polluted seriously and formed oxidation film. Use the toothpaste to polish the platinum or gold surface. Use purified water to clean. Dip it into the 3.5mol/L potassium chloride solution for 6 hours.

(4) Do not plug in or pull out the USB port frequently. The minimum interval is 2s.